Ways to Optimize Your aluminum casting Process for Better Results

Wiki Article

Comprehending Aluminum Casting: A Comprehensive Overview to Its Advantages and Applications

Aluminum casting is a process that transforms liquified aluminum right into strong types via different strategies. This technique uses notable advantages, such as lightweight toughness and deterioration resistance. It finds applications in countless markets, mirroring its versatility. Nevertheless, understanding the complexities of aluminum casting and its ideal techniques can substantially impact the top quality of the end product. Discovering these elements discloses truth possibility of aluminum casting in modern manufacturing.The Basics of Aluminum Casting

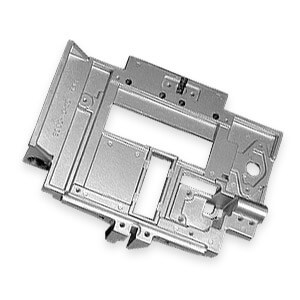

Aluminum casting is a manufacturing procedure that changes molten aluminum right into strong objects through numerous techniques. This procedure starts with home heating aluminum until it reaches its melting factor, permitting it to stream into molds. There are several techniques of aluminum casting, consisting of sand casting, pass away casting, and investment casting, each suitable for various applications based on layout intricacy and production quantity.In sand casting, molds are created making use of sand, supplying adaptability for elaborate forms. Die casting includes forcing molten aluminum right into a steel mold and mildew under high stress, causing exact and repeatable components. Investment casting, on the various other hand, utilizes a wax pattern that is coated with ceramic to develop detailed elements.

After the aluminum cools down and strengthens, the molds are removed, disclosing the completed items. This casting process is important in various markets, consisting of auto, aerospace, and durable goods, enabling the production of long lasting and light-weight elements.

Advantages of Aluminum Casting

One of the key benefits of aluminum casting depends on its capacity to generate light-weight yet solid parts. This special combination makes aluminum an ideal option for numerous sectors, consisting of automotive, aerospace, and durable goods. The inherent deterioration resistance of aluminum additionally enhances the toughness of the cast elements, lengthening their life-span and decreasing the requirement for upkeep.

Additionally, aluminum casting enables for complicated geometries and detailed designs, which can cause more efficient and visually pleasing products. The product's superb thermal and electrical conductivity additionally broadens its applications, specifically in electronics and warm exchangers.

Additionally, aluminum recycling is very reliable, contributing to environmental sustainability and lowering production expenses. Overall, the benefits of aluminum casting position it as a sensible and functional solution for suppliers looking for to maximize performance while decreasing weight and resource usage.

Typical Techniques of Aluminum Casting

While various strategies exist for aluminum casting, each approach supplies distinct advantages tailored to particular applications. The most common methods consist of sand casting, die casting, and financial investment casting.Sand casting, understood for its convenience, utilizes sand molds to create complex shapes and appropriates for both little and large manufacturing runs. Die casting, on the various other hand, employs high-pressure shot of liquified aluminum into steel molds, resulting in smooth surfaces and accurate dimensions, making it ideal for mass production.

Investment casting, often referred to as lost-wax casting, entails developing a wax pattern coated with a ceramic covering. aluminum casting. Once the wax is disappeared, molten aluminum is put into the tooth cavity, producing complex layouts and outstanding surface coatings

Each of these techniques plays a vital function in the aluminum casting landscape, providing details advantages that accommodate varying manufacturing requirements and manufacturing ranges.

Applications Across Industries

The adaptability of aluminum casting methods enables a wide variety of applications throughout numerous markets. In the automobile field, lightweight aluminum elements enhance gas efficiency and efficiency, contributing to the growing need for electric cars. Aerospace industries use aluminum spreadings for their strength-to-weight ratio, guaranteeing safety and toughness in airplane production.The building and construction industry gain from aluminum casting with building aspects and structural parts that resist deterioration and need very little upkeep. Additionally, customer electronic devices suppliers employ aluminum spreadings for structures and housings, balancing visual appeals with capability.

In the aquatic sector, aluminum castings are favored for boats and marine tools as a result of their resistance to saltwater corrosion. The medical field utilizes aluminum castings in surgical instruments and tools, ensuring accuracy and reliability. Generally, aluminum casting's versatility enables it to meet the varied demands of multiple fields, making it a vital manufacturing procedure.

Ideal Practices for Successful Aluminum Casting

Effective aluminum casting counts on a combination of careful prep work, exact execution, and detailed quality assurance. At first, choosing high-grade aluminum alloys is crucial, as they directly influence the casting's residential or commercial properties and efficiency. Correct mold and mildew design is critical, guaranteeing that it accommodates thermal contraction and lessens issues.Throughout the melting process, maintaining the correct temperature and staying clear of contamination are essential to attaining an uniform alloy. In addition, using effective putting strategies can improve the filling of molds, minimizing the probability of air pockets or additions.

Post-casting, carrying out comprehensive examination approaches, such as visual analyses and non-destructive testing, guarantees that issues are identified early. Moreover, utilizing strenuous quality assurance steps throughout the process assists preserve consistency and dependability in the end products. By sticking to these best methods, producers can considerably improve the success and effectiveness of their aluminum casting operations.

Frequently Asked Inquiries

What Security Measures Should Be Taken Throughout Aluminum Casting?

Exactly How Can Defects in Aluminum Castings Be Minimized?

Issues in aluminum spreadings can be minimized through careful mold and mildew style, correct temperature control, making sure tidy metal, making use of check here appropriate pouring strategies, and performing detailed inspections to recognize and resolve concerns prior to finalizing the casting procedure.

What Is the Ecological Influence of Aluminum Casting?

The ecological effect of aluminum casting consists of energy-intensive procedures, greenhouse gas emissions, and source removal worries. Improvements in recycling and lasting methods can reduce these impacts, promoting an extra eco-friendly approach to aluminum production.Can Aluminum Casting Be Reused?

Yes, aluminum casting can be reused effectively. The recycling process needs substantially less power compared to primary aluminum manufacturing, making it an environmentally pleasant option that adds to source preservation and minimized carbon emissions.What Are the Prices Linked With Aluminum Casting Processes?

Expenses related to aluminum casting processes include product expenditures, labor, tools upkeep, power consumption, and mold construction. These aspects can differ significantly based upon production range, complexity of designs, and specific production techniques employed.Aluminum casting is a procedure that changes molten aluminum right into strong types through numerous methods. Aluminum casting is a manufacturing process that changes liquified aluminum into solid items with various strategies. While various strategies exist for aluminum casting, each method supplies unique benefits tailored to particular applications. The ecological effect of aluminum casting includes energy-intensive processes, greenhouse gas exhausts, and source extraction issues. Prices connected with aluminum casting procedures consist of material expenditures, labor, devices upkeep, power usage, and mold and mildew manufacture.

Report this wiki page